Power Plant Dust Collection Fiberglass Bag Filter (120*3600)

Basic Info

Model No.: fiberglass

Product Description

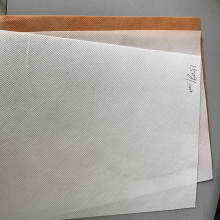

Power Plant Dust Collection Fiberglass Bag Filter (120*3600) ECOGRACE Woven Fiberglass Fabric Filter Bag : ECOGRACE fiberglass filter cloth Filter Bags are the optimum solution for Dust Collection Systems with working temperatures 150- 260 degree °C. ECOGRACE develop and research the chemical finishing on the fiberglass filter cloth to fully utilize the chemical and physical function . It includes PTFE membrane , PTFE dipping , Graphite treatment , silicon treatment .ECOGRACE Finished woven fiberglass bags are successfully used in Reverse air dust collection system , pulse jet Bag Filter dust collection system and shaking vibrating dust collecting system . The applied industry including cement plant , carbon black processing , Silicon furnace , Ferrous Silicon Manganese smelting furnace , Coal Boilers , steel mill . Features: 1. High temperature resistant , it can work for a long time under 260-280 °C. 2. Smooth surface is good for easy dust cake releasing , energy saving . 3. Steady size,non shrinking under proper temperature. 4. Intensity high, obstruction more than 99% code thickness. Industrials Applications: • Cement Plant • Coal Boiler • Wast incinerators • Carbon black production • Refineries • Steel Mills Foundary / metal smelting furnace Metal Smelting Non ferros alloy plant Paper plant , Glass production plant . E-Glass Fiber Finished filter cloth specification:

ECOGRACE Fiberglass Filter Bag Chemical Finishing : GSP finished:It consists blend of silicon oils, graphite & PTFE ( Teflon ). The three finishes components combine to protect the glass fabric from abrasion , but offer only limited protection from chemical attack. The GSP finish is now widely primarily in cement production and metal foundry applications . PTFE finished:10 % add-on of PTFE particles encapsulates the glass fibers to prevent abrasion.Recommended for use with utility base load boilers operating under mild pH conditions. Acid Resistent treatment ( AR ) :Consists of acid resistant polymers,PTFE , graphite , and silicon treatment . Recommended for filtration of flue gases in industrial utility boilers and acid environments such as carbon black and fossil fuel burning power generation . e-PTFE membranes: Coated with e-PTFE membranes With the surface finished, it enjoys such characters as smooth, much lower emission , high temperature resistant , chemical corrosion repellent , high tensile breaking strength ,easy cleaning .  Contact us if you need more details on Fiberglass Filter Bag. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Dust Collection、Bag Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Fiberglass Filter Bag. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Dust Collection、Bag Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

| Item No. | LOI (%) | Weave | Weight (g/m2) | Mullen burst (kpa) | Tensile strength (N/2.5cm) | Air permeability(cm3/cm2/s·127pa) | Finished | Running temperature (°C) | |

| warp | weft | ||||||||

| EFA301 | > 10 | double twill | 780-850 | > 6200 | > 2400 | > 2000 | 15-30 | PTFE | <260 |

| EFI301 | > 10 | double twill | 780-850 | > 6200 | > 2400 | > 2000 | 15-30 | PI | <260 |

| EFB302 | > 2 | 1/3 twill | 450-500 | > 4500 | > 2000 | > 1200 | 20-36 | GSP | <260 |

| EFC302 | > 5 | 1/3 twill | 340-380 | > 4500 | > 2000 | > 1200 | 20-36 | AR | <260 |

| EFA303 | >10 | 1/3 twill | 320-360 | > 3500 | > 1400 | > 800 | 22-35 | PTFE | <260 |

| EFC303 | > 5 | 1/3 twill | 900-950 | > 3400 | > 1200 | > 700 | 22-35 | AR | <260 |

| EFD502 | > 7 | satin | 900-950 | > 8000 | > 3000 | > 2400 | 15-25 | PD | <400 |

| EFA404 | > 10 | double twill | 800-850 | > 5000 | > 2600 | > 2200 | 15-30 | PTFE | <260 |

| EFE201 | >1.7 | satin | 550-600 | > 5500 | > 2200 | > 2000 | 20-35 | PG | <260 |

| EFE203 | > 1.7 | 1/3 twill | 550-600 | > 5500 | > 2200 | > 2000 | 20-35 | PG | <260 |

Contact us if you need more details on Fiberglass Filter Bag. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Dust Collection、Bag Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Fiberglass Filter Bag. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Dust Collection、Bag Filter. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Dust Collector Filter Bags > Fiberglass Filter Bags

Premium Related Products

Other Products

Hot Products

PA (polyamide) filter cloth for industrial filter pressNOMEX felt belt dust filtersECOGRACE high temperature resistant fiberglass cloth dust filter bag fabricECOGRACE chemical industry strong acid resistant PTFE sewing threadECOGRACE Silicon Industrial PPS cloth dust filter bag cageair dust filter socks filter bagCoal Washing 30-100 micron polyester press filter fabricsPolyimide high temperature resistance dust filter big (P84)Water and Oil Repellent dust bag Filter PPS Filter Bagindustrial dust Filter media filter fabric bagIndustrial Boiler Smoke Bag Filter dust collecting machineStone Crusher Dust Collecting system Bag Filter750 Gsm Dust Collection Filter Bags Cement Plant Kiln Bag Filter700gsm fabric dust collector PTFE filtration bag0.1um, 30'' 226fin PE liquid filter cartridgeAsphalt mixing plant Nomex Filter bag dust bag filter