Industrial filter systems fly ash bag house cement plant central silo coal dust collector, filters for dust collector

Product Description

Product Description

Entex has rich experience in the demanding dust and fume extraction & filtration industry. we can help to provide a thorough knowledge of air pollution control. We provide Dust Collection Systems design, manufacture, service for a wide range of applications, coupled with a continuing evaluation of industrial ventilation systems. FEATURES: Our baghouse Dust Collectors offer continuous-duty performance for uninterrupted operation of industrial processes. While the collector is running, the self-cleaning system delivers dust from the Filter Bag to the hopper, allowing the collector to maintain constant airflow and consistent performance. Entex offers baghouse collectors to meet all types of industrial needs. In addition, dust collectors may be custom sized and equipped for special applications.

The type of Industrial Dust Collector you need, as well as the final ventilation system design, depends on several “key” factors. These include the collected particulates’ physical and chemical composition, process exhaust conditions of temperature and moisture, and both local regulations.

Importance of Industrial Dust Collection Systems Effective industrial dust collection system designs provide: * Employee protection from the harmful effects of air pollutants in the form of dust, fumes, and mists; * Facilities that are compliant with safety, occupational health and air emission regulations; * Protection for the local environment from air pollutants generated by manufacturing processes; * Personnel and facility safety in the form of explosion protection when handling combustible dust; * Attenuation of excessive noise, either as personnel hearing protection or adherence to sound levels at the property line. Dust Collection System Design Considerations Dust, fume, and mist collection system design is about: * Maintaining airflow thru the system to minimize particulate and material deposition; * Minimizing noise levels from components; * Minimizing the pressure loses thru the system with proper duct and fitting configuration; * Minimizing horsepower requirements; * Maximizing capture with hoods with correct airflow; * Maintaining the integrity of duct and components by selection of proper materials of construction. Typical Dust Collection System Components Dust Collectors – Dust Collector designs are available to handle most dust encountered. Whether bags, cartridges, pleated bags, blanket media, or box filters, maximizing collection efficiency with filter media longevity is the goal. Understanding of the materials being collected, before equipment selection, will ensure these criteria are met. Entex can help with more dust collection system components contains explosion protection, industrial dampers and louvers, industrial duct systems, flexible connectors, industrial Exhausters, fan silencers, electrical controls, etc.

Uses:

Baghouse dust collectors provide excellent performance for heavy dust-loading operations involving fine to moderately sized dust, including tough to handle particulates, such as curly, sticky, or abrasive particles of wood or metal shavings, hydroscopic dust, or paper shreds. Baghouse dust collectors provide effective performance for industrial operations such as sanding, chipping, planning, bailing, processing, blasting, and cutting.

Dust Filter Bags" class="magic-0">See More Dust Filter Bags

Our wide and varied range of products are suitable for different applications and industries.

Please feel free to contact us if you have any questions!

Working Environment | Product Name | Weight (g/m2) | Thickness (mm) | Air permeability (m3/m2.min) | Temperature Resistance (°C) | ||

Continues | Instant | ||||||

Room Temperature | Polyester Needle Felt | 450-700 | 1.6-2.2 | 8-18 | 130 | 150 | |

Polypropylene Needle Felt | 400-600 | 1.6-2.4 | 8-20 | 80 | 100 | ||

Acylic Needle Punched Felt | 500-600 | 1.8-2.2 | 8-20 | 130 | 150 | ||

PTFE Membrane Needle Punched Felt | 450-600 | 1.6-2.2 | 2-4 | 130 | 150 | ||

High-temperature Chemical Fiber | PPS Needle Punched Felt | 400-650 | 1.4-2.2 | 8-20 | 160 | 190 | |

P84 Needle Punched Felt | 500-600 | 1.8-2.4 | 8-20 | 250 | 280 | ||

PTFE Needle Punched Felt | 650-800 | 0.8-1.2 | 8-20 | 240 | 260 | ||

Aramid (Nomix, Conex) Needle Punched Felt | 450-550 | 1.7-2.4 | 8-20 | 204 | 240 | ||

High-temperature Fiberglass Compound | Fiberglass, PPS Compound Felt | 900±50 | 2.2-2.8 | 22±5 | 190 | 232 | |

Fiberglass, Aramid Compound Felt | 900±50 | 2.2-2.8 | 22±5 | 204 | 240 | ||

Fiberglass, P84 Compound Felt | 900±50 | 2.2-2.8 | 22±5 | 260 | 280 | ||

Fiberglass, PTFE Compound Felt | 900±50 | 2.2-2.8 | 22±5 | 280 | 300 | ||

Recommend Products

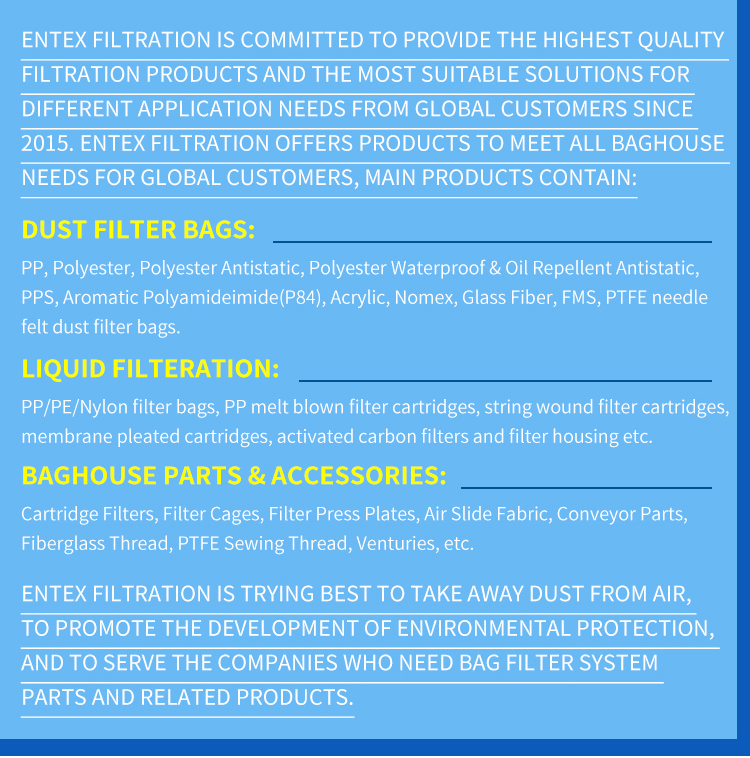

About Us

Certifications

FAQ

Q: Are you a trading company or a manufacturer?

A: We have our own factory.

Q: Do you support OEM made?

A: OEM is warmly welcomed, we can arrange your own color or label, print your OEM package, and make your own shape according to your drawing.

Please feel free to contact us if you have any questions.

Q: Do you support OEM made?

A: OEM is warmly welcomed, we can arrange your own color or label, print your OEM package, and make your own shape according to your drawing.

Q: Do you provide samples ? is it free or extra?

A: Yes, we could offer the sample for free charge, you only have to pay the cost of freight.

A: Yes, we could offer the sample for free charge, you only have to pay the cost of freight.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: How's the after-sale service?

A: We’ll take photos for your check before loading container and confirm all of documents within 48 hours after shipment. For any other supplier order,you just ask them to deliver us for combine container,we’ll do this favor to arrange everything very well.

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: How's the after-sale service?

A: We’ll take photos for your check before loading container and confirm all of documents within 48 hours after shipment. For any other supplier order,you just ask them to deliver us for combine container,we’ll do this favor to arrange everything very well.

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Please feel free to contact us if you have any questions.

Product Categories : Dust Collector

Premium Related Products

Other Products

Hot Products

PA (polyamide) filter cloth for industrial filter pressNOMEX felt belt dust filtersECOGRACE high temperature resistant fiberglass cloth dust filter bag fabricECOGRACE chemical industry strong acid resistant PTFE sewing threadECOGRACE Silicon Industrial PPS cloth dust filter bag cageair dust filter socks filter bagCoal Washing 30-100 micron polyester press filter fabricsPolyimide high temperature resistance dust filter big (P84)Water and Oil Repellent dust bag Filter PPS Filter Bagindustrial dust Filter media filter fabric bagIndustrial Boiler Smoke Bag Filter dust collecting machineStone Crusher Dust Collecting system Bag Filter750 Gsm Dust Collection Filter Bags Cement Plant Kiln Bag Filter700gsm fabric dust collector PTFE filtration bag0.1um, 30'' 226fin PE liquid filter cartridgeAsphalt mixing plant Nomex Filter bag dust bag filter